TECHNOLOGY & INNOVATION

We firmly believe that technology should serve man, and not the other way around.

At Favari Mobili, human action is never passive, but an integral, fundamental part of the production process.

Our work revolves around creativity, ingenuity and manual skills, these being fixed values that no technology can ever fully replace.

The first steps

Combining the past with the present does not mean forgetting traditions, but rather treasuring the oldest secrets and skills,

while opening the door to the future. The very best in craftsmanship combined with the latest technology: this is the very essence of Favari's production processes.

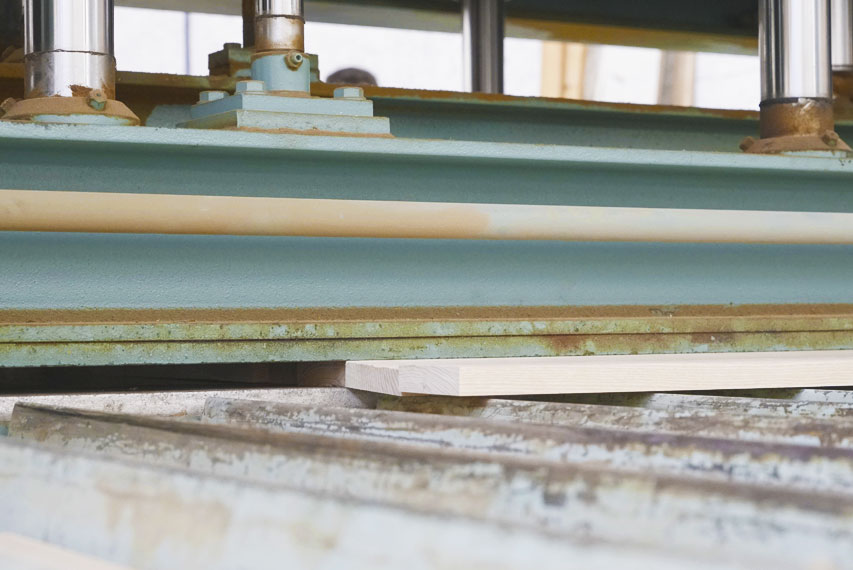

Timber and panel sorting and sawing

We choose wood boards of different essences, such as Canaletto walnut, ash, beech, linden, birch, mahogany, cedar, chestnut, fir and pine, from our warehouse. We buy these from trusted retailers in Italy or directly from sawmills, giving preference to wood from managed reforestation areas.

Trunk and panel

processing

We can also start to process the log directly with our in-house log saw (like those in sawmills).This allows us to have total control of the production cycle, taking care of the very first phase of sawing, seasoning and drying.

As for the panels, we use those which are CARB2 certified with very low formaldehyde emissions.

CARB2 is the certification currently required for exports to the USA and to California in particular.

The second steps

In today’s day and age, a history of craftsmanship meets the latest modern technology.Favari is a company which picks up on every innovation, ready to welcome change and all the improvements it can bring with it, without forgetting the constantly growing need for sustainability.

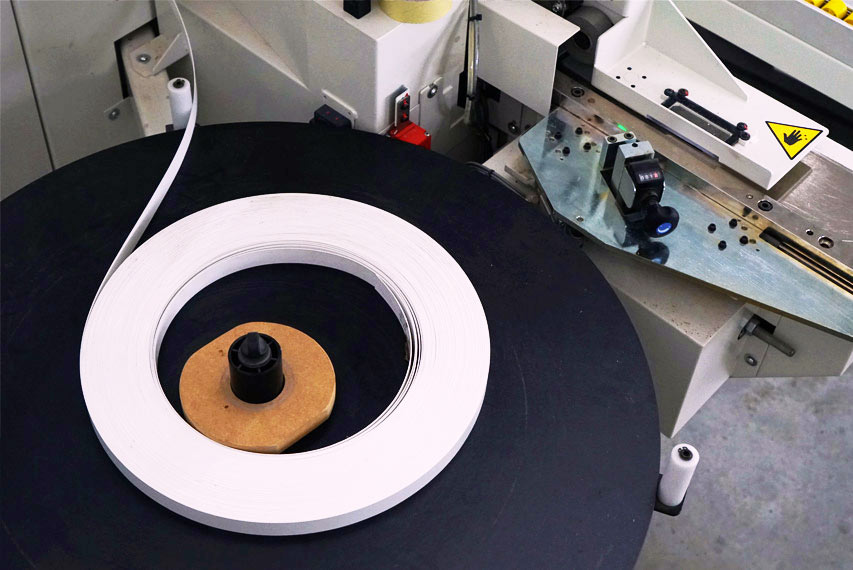

Edging

Panels up to 60 mm in thickness which need to be edged, using EVA or PU glues, are edged with different types and finishes:Wood, Melamine, Abs, Abs/Aluminium.

Applying protective film edges on panels with a delicate surface is not a problem.

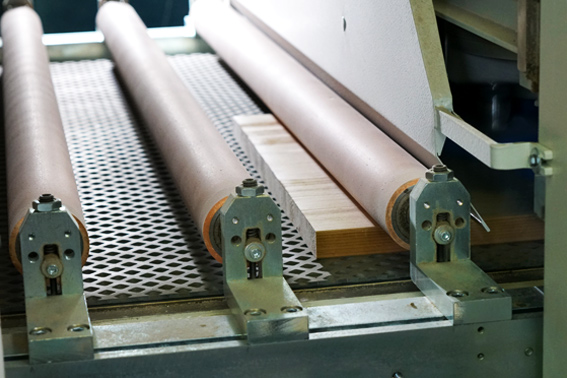

Sanding line.

Surface finishing centre

The machine is equipped with a planetary unit that has revolutionised the finishing processes for wood products: not only can it be used for an extremely wide range of processes, but it can also achieve an exceptional finish.

The multi-directional action of the planetary unit makes it particularly effective: the unit’s 3 movements (rotation of the abrasive brushes, counter-rotation of the brush holder discs and lateral shifting of the head) guarantee a performance that cannot be achieved with traditional sanding units.

Removing scratches against the grain present in door transoms, improving the finish after traditional sanding with the grain, removing the raised fibre for wood intended for ecological water-based varnishing, opening the wood pore, multi-directional structuring (rusticating), edging raw or painted panels, making colours and primers uniform ("ragging"), superfinishing painted panels in preparation for applying direct polishes.

Varnishing and upholstery

We only entrust certain processing steps to trusted partners.Thanks to our partnerships with tried-and-tested local companies, we only carry out varnishing and upholstery work externally.Wherever possible, we favour non-toxic varnishing carried out in a completely water-based cycle, with atmospheric emission class A+.

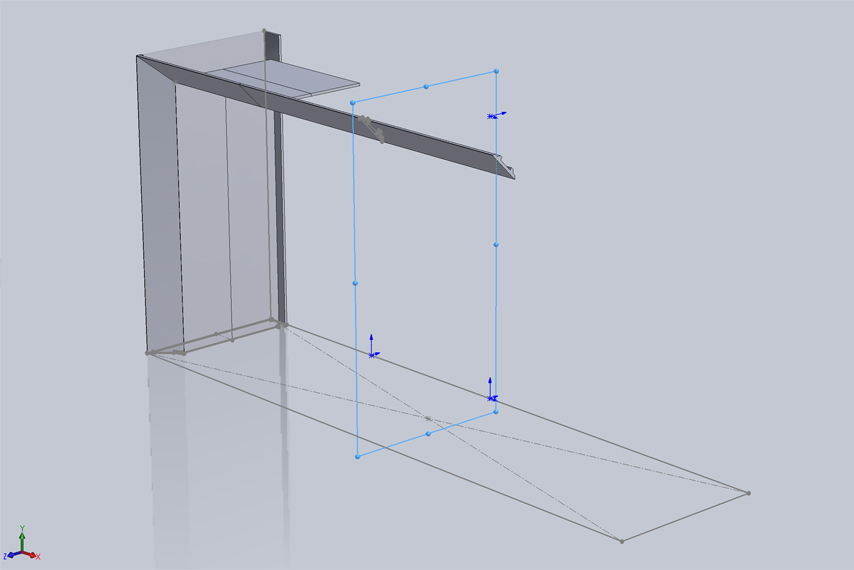

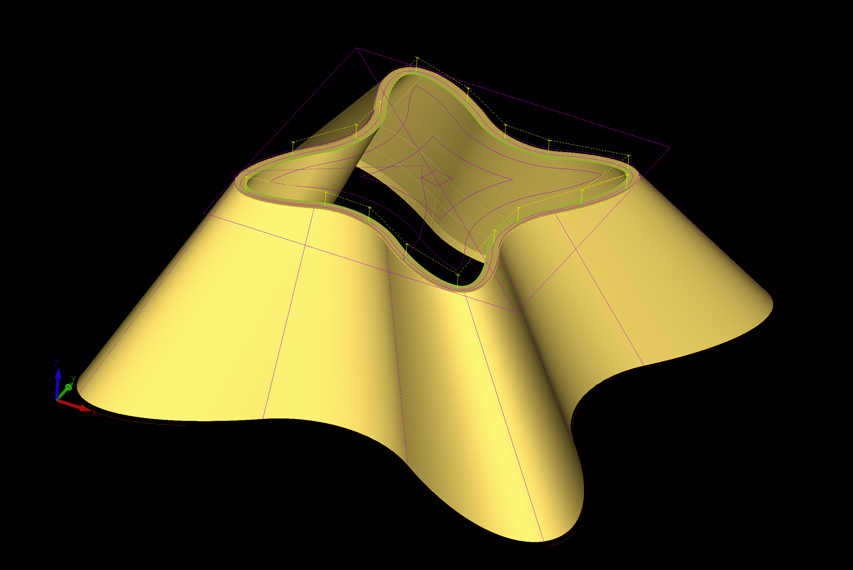

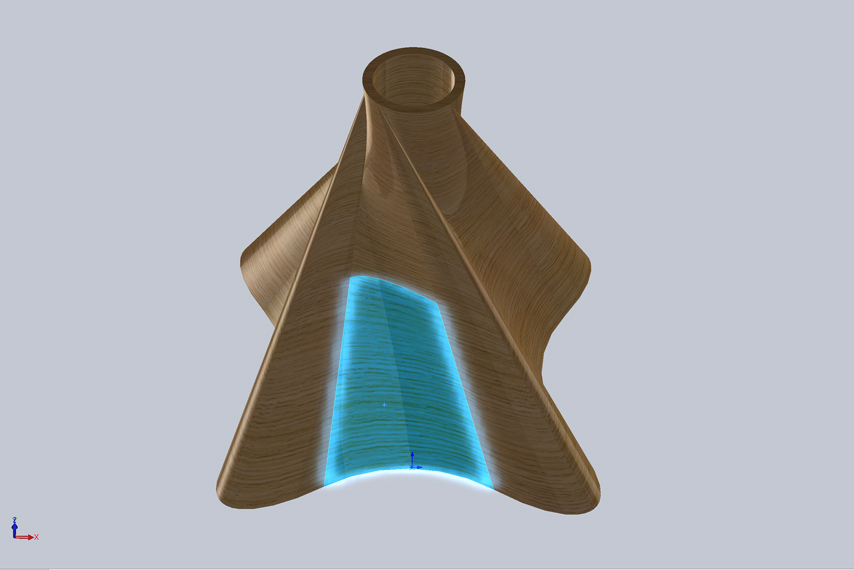

2D and 3D machining

We give shape to ideas by processing 3D faces for the production of furniture components,

moulds, prototypes and design objects of the most varied shapes.

These are processes that make it possible to satisfy the needs of a wide range of usages, from design elements in wood to plastic and advanced material applications (option to process Solid Surface elements, such as sinks and curved components, therefore not only wood).

CNC machining centre

5-axis

working volume 4970 x 1600 x 500

CNC machining centre

5-axis

working volume 6880 x 1560 x 320

Process checks and quality controls

Every stage of production, from order acceptance to delivery, is monitored using computer systems and barcodes.This way, it is possible to know the progress of each order in real time, giving the customer a reliable, safe and punctual service.

Production management and monitoring

Every stage of production, from order acceptance to delivery, is monitored using computer systems and barcodes.This way, it is possible to know the progress of each order in real time, giving the customer a reliable, safe and punctual service.

Quality policy

Our quality policy follows principles aimed primarily at customer satisfaction. We are never totally satisfied with the work done and we try to improve every aspect, aiming high towards perfection. But this positive spiral cannot be achieved overnight; it is the result of hard work involving analysis, self-criticism and concrete corrective action, following the good practice of:"write what you do and do what you write." "Quality is not an obligation, but an opportunity for continuous growth".